Note: This series concerns a proposal to use incineration to recycle lithium-ion batteries. It was proposed for Endicott in Broome County NY. The proposal resulted in the formation of the group NoBurnBroome on April 15, 2020, to oppose the proposal, which it successfully accomplished in February 2021. The Fluoride Action Network was interested in this project because the novel use of incineration to recoup valuable metals would be a new, and non-assessed, exposure route to large amounts of hydrogen fluoride. Index to the series is here.

The following studies were shared with officials and residents to demonstrate that there were alternatives to the use of incineration in the recycling of lithium-ion batteries.

January 27, 2021. Jung JCY, Sui PC Zhang J. A review of recycling spent lithium-ion battery cathode materials using hydrometallurgical treatments. Journal of Energy Storage 35-102217.

November 16, 2020. Mapping the European reverse logistics of electric vehicle batteries. Master Thesis by William Bergh.

Excerpt from abstract:

“Lithium ion batteries enable the implementation of renewable energy and electric vehicles, both of which are crucial for the transition to a sustainable society. Due to environmental, economic and political reasons, these batteries must be recycled efficiently. Most lithium ion batteries are placed on the market in electric vehicles, which are reaching end-of-life at an exponential pace, prompting the need to rapidly develop an efficient reverse supply chain of electric vehicle batteries. Due to the market speed, the complex ecosystem of actors and regulations and the inherent dangerous properties of lithium ion batteries, this reverse supply chain is still in its infancy and yet to be well understood…”

November 12, 2020. Xu P, Dai Q, Gao H, Liu H, et al. Efficient Direct Recycling of Lithium-Ion Battery Cathodes by Targeted Healing. Joule 4(12):2609-2626.

Graphical Abstract

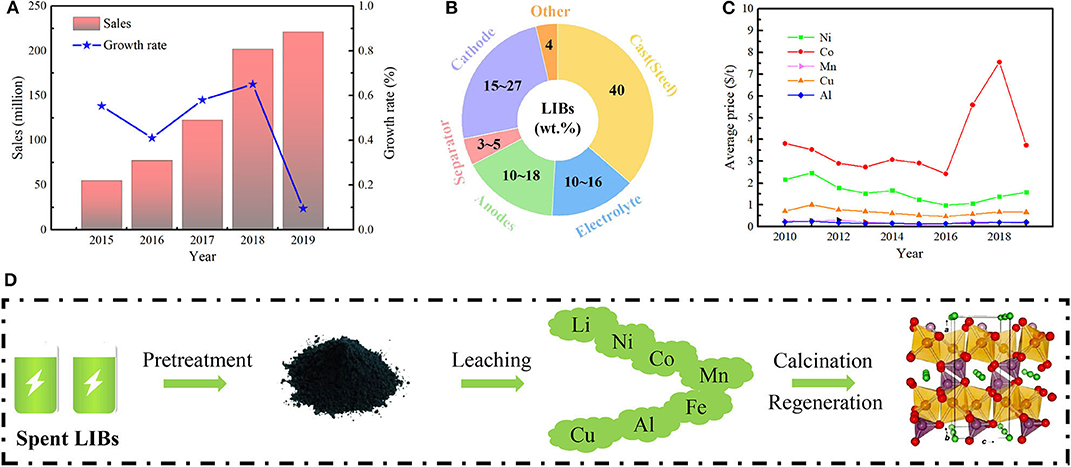

October 29, 2020. Zhao Q, Hu L, Li W, et al. Recovery and Regeneration of Spent Lithium-Ion Batteries From New Energy Vehicles. Frontiers in Chemistry.

Excerpt: It is of great economic, environmental and social benefit to discover harmless treatment and resource utilization options for spent lithium-ion batteries (LIBs), which contain a large proportion of valuable metal elements (e.g., Li, Ni, Co, Mn, Cu, and Al) and poisonous chemicals (e.g., lithium hexafluorophosphate and polyvinylidene fluoride). The present work summarized the leading technologies and hot issues in the disposal of spent LIBs from new energy vehicles. Moreover, development of the trend of innovative technologies for the recycling of spent LIBs is recommended.

October 25, 2020. Anwani S, Methekar R, Ramadesigan V. Resynthesizing of lithium cobalt oxide from spent lithium-ion batteries using an environmentally benign and economically viable recycling process. Hydrometallurgy 197:105430.

October 8, 2020. Qiao D, Wang G, Gao T, Wen B, Dai T. Potential impact of the end-of-life batteries recycling of electric vehicles on lithium demand in China: 2010–2050. Science of The Total Environment.

2020. Zhou S, et al. Recycling of LiCoO2 cathode material from spent lithium ion batteries by ultrasonic enhanced leaching and one-step regeneration. Journal of Environmental Management 277:111426.

September 20, 2020. Sommerville R, Shaw-Stewart J, Goodship V, et al. A review of physical processes used in the safe recycling of lithium ion batteries. Sustainable Materials and Technologies.

September 2020. Zhao Y, Liu B, Zhang L, Guo S. Microwave Pyrolysis of Macadamia Shells for Efficiently Recycling Lithium from Spent Lithium-ion Batteries. Journal of Hazardous Materials 396:122740.

September 2020. Bi et al. Low-temperature thermal pretreatment process for recycling inner core of spent lithium iron phosphate batteries. Waste Management & Research: The Journal for a Sustainable Circular Economy.

September 2020. Pindar S, Dhawan N. Rapid recycling of spent lithium-ion batteries using microwave route. Process Safety and Environmental Protection.

August 2020. Wu Z, Soh T, Chan JJ, Meng S, Meyer D, Srinivasan M, Tay CY. Repurposing of Fruit Peel Waste as a Green Reductant for Recycling of Spent Lithium-Ion Batteries. Environmental Science & Technology 54(15):9681-9692. Supporting information at es0c02873_si_001.pdf (358.26 kb)

August 2020. Fan E, Shi P Zhang X, Lin J, et al. Glucose oxidase-based biocatalytic acid-leaching process for recovering valuable metals from spent lithium-ion batteries. Waste Management 114:166-173. Graphic abstract:

August 2020. Binder JO, Culver SP, Zeier WG, Janek J. A Rapid and Facile Approach for the Recycling of High?Performance LiNi1?x?yCoxMnyO2 Active Materials. ChemSusChem.

August 2020. Wang M, Tan Q, Liu L, Li J. Selective regeneration of lithium from spent lithium-ion batteries using ionic substitution stimulated by mechanochemistry. Journal of Cleaner Production.

July 2020. Yu S, Xiong J, Wu D, Lu X, et al. Pyrolysis characteristics of cathode from spent lithium-ion batteries using advanced TG-FTIR-GC/MS analysis. Environmental Science and Pollution Research.

July 2020. Lombardo et al. Incineration of EV Lithium-ion batteries as a pretreatment for recycling – Determination of the potential formation of hazardous by-products and effects on metal compounds. Journal of Hazardous Materials. 393:122372.

June 2020. Mossali et al, Lithium-ion batteries towards circular economy: A literature review of opportunities and issues of recycling treatments. Journal of Environmental Management 15:110500.

| Table 3. Economic value of Lithium-ion batteries components, Mossali et al. | |||

| Value (US $ per ton) | |||

| Cathode components | 2001 | 2017 | 2019 |

| Aluminum | $1,250 | $2,000 | $1,800 |

| Lithium | $7,500 | $9,000 | $10,000 |

| Cobalt | $38,000 | $55,000 | $35,500 |

| Nickel | $8,600 | $10,000 | 13,200 |

| Manganese | $1,100 | $2,000 | $2,000 |

| Anode components | |||

| Copper | $1,800 | $5,500 | $5,800 |

| Graphite | $550 | $1,000 | $800 |

May 2020. Li et al. Water-Based Electrode Manufacturing and Direct Recycling of Lithium-Ion Battery Electrodes—A Green and Sustainable Manufacturing System. iScience [Epub before print].

March 2020. Liu J, Wang H, Hu T, Bai X, et al. Recovery of LiCoO2 and graphite from spent lithium-ion batteries by cryogenic grinding and froth flotation. Minerals Engineering 148: 106223.

March 2020. Meshram et al. Environmental impact of spent lithium ion batteries and green recycling perspectives by organic acids – A review. Chemosphere 242: 125291.

March 2020. Weichenthal S, Olaniyan T, Christidis T, et al. Within-city Spatial Variations in Ambient Ultrafine Particle Concentrations and Incident Brain Tumors in Adults. Epidemiology 31 (2):177-181.

January 2020 Xiao J, Li J, Xu Z. Challenges to future development of spent lithium ion batteries recovery from environmental and technological perspectives. Environmental Science & Technology 54(1):9–25.

August 2019. Velázquez-Martínez O, Valio J, Santasalo-Aarnio A, Markus Reuter M, Serna-Guerrero R. Critical Review of Lithium-Ion Battery Recycling Processes from a Circular Economy Perspective. Batteries 5(4), 68;

2019. Jacody M. It’s time to get serious about recycling lithium-ion batteries. C&EN (Chemical & Engineering News). July 14.

2019a. Wang M, Tan Q, Liu L, Li J. A low-toxicity and high-efficiency deep eutectic solvent for the separation of aluminum foil and cathode materials from spent lithium-ion batteries. Journal of Hazardous Materials 380:120846.

2019b. Wang M, Tan Q, Liu L, Li J. Efficient separation of aluminum foil and cathode materials from spent lithium-ion batteries using a low-temperature molten salt. ACS Sustainable Chemistry & Engineering 7:8287–8294.

2019. Matek B, Dorn J, Divita F. Life Cycle Assessment: C4V Lithium-Ion Battery Cells for Electric Vehicles. Report Number 19-44. Prepared for New York State Energy Research and Development Authority (NYSERDA), Albany, NY.

2018. Gaines L, Richa K, Spangenberger J. Key issues for Li-ion battery recycling. Energy & Sustainability 5:E14.

2018. Gao W, Liu C, Cao H, Zheng X, et al. Comprehensive evaluation on effective leaching of critical metals from spent lithium-ion batteries. Waste Management 75:477–485.

2018. Natarajan S, Aravindan V. Recycling strategies for spent Li-ion battery mixed cathodes. ACS Energy Letters 3(9):2101–2103

2017. Larsson F, Andersson P, Blomqvist P, Mellander BE. Toxic fluoride gas emissions from lithium-ion battery fires. Scientific Reports 7:10018. March 22.

2017. Prabaharan et al. Electrochemical process for electrode material of spent lithium ion batteries. Waste Management 68:527-533.

2017. Swain B. Recovery and recycling of lithium: A review. Separation and Purification Technology 172:388-403.

2017. Xiao J, Li J, Xu Z. Novel approach for in situ recovery of lithium carbonate from spent lithium ion batteries using vacuum metallurgy. Environmental Science & Technology 51(20):11960–11966.

2014. Chen X, Zhou T. Hydrometallurgical process for the recovery of metal values from spent lithium-ion batteries in citric acid media. Waste Management and Research 32(11):1083–1093.

2014. Gaines L. The future of automotive lithium-ion battery recycling: Charting a sustainable course. Sustainable Materials and Technologies 1-2:2-7.

2014. Zeng X, Li J. Innovative application of ionic liquid to separate Al and cathode materials from spent high- power lithium-ion batteries. Journal of Hazardous Materials 271:50–56.

2012. Choi S, Kim Y. Microstructural analysis of poly (vinylidene fluoride) using benzene derivative pyrolysis products. Journal of Analytical and Applied Pyrolysis 96:16–23.

1994. Zulfiqar S, Rizvi M, Munir A, McNeil IC. Study of the thermal degradation of polychlorotrifluoroethylene, poly (vinylidene fluoride) and copolymers of chlorotrifluoroethylene and vinylidene fluoride. Polymer Degradation and Stability 43(3):423– 430.

1990. O’Shea ML, Morterra C, Low MJD. Spectroscopic studies of carbons. XVII Pyrolysis of polyvinylidene fluoride. Materials Chemistry and Physics 26(2):193–209.

Index to the Endicott NY campaign, 2020-2021

Part 1: The proposal in Endicott NY

Part 2: Background on IBM pollution in Endicott NY

Part 3: 10 Arguments Against the SungEel Proposal for Endicott NY

Part 4: Lithium-ion Battery Recycling: Position Paper of No Burn Broome

Part 5: Key Documents for the proposal in Endicott NY

Part 6: Local News Articles from NY state

Part 7: News – National & International

Part 8: Studies/Reports on alternatives to the use of incineration

Part 9: Timeline of NoBurnBroome’s campaign

Part 10: What are PFAS?