Note from Fluoride Action Network:

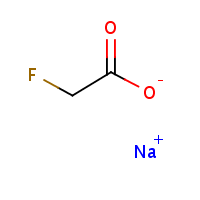

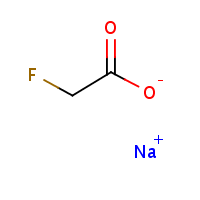

Molecular structure of highly toxic Sodium fluoroacetate (known as 1080). For more info, albeit outdated, click here

A Rolleston-based pest bait manufacturing organisation has been fined $275,000 after an employee was poisoned and nearly lost his life.

Pest Control Research Limited Partnership (PCR) appeared for sentencing in the Christchurch District Court yesterday. In addition to the fine given, a reparation of $8,177 was ordered, and costs of more than $96,600 was awarded to WorkSafe.

The worker spent four weeks in hospital being treated for fluoroacetate poisoning and a further two months recuperating out of hospital.

“His urine fluoroacetate reading was more than 500 times higher than WorkSafe’s Biological Exposure Index limit and he was extremely lucky to survive.” Head of specialist snterventions Dr Catherine Gardner said.

The frightful incident happened in May 2019 at PCR, a company which manufactures pest control products including baits containing sodium fluoroacetate (more commonly known as 1080) as the toxic active ingredient.

In 2018 and 2019, PCR was experiencing issues with the ongoing supply of sodium fluoroacetate and set up an internal project codenamed the “Home Brew Project” or “Project X” to manufacture its own supply of the highly toxic substance.

The incident occurred during the first trial production of sodium fluoroacetate when a runaway chemical reaction resulted in a loss of containment.

“Health and safety requirements were not met from the very start of this project and cumulatively designed.”

“Fabrication and process errors ultimately resulted in workers being exposed to highly toxic vapour from a failure in the manufacturing process and in PCR’s overall safety management systems.”

The work was being undertaken inside a purpose-built self-contained chemical processing container inside an empty industrial unit in Bromley, Christchurch.

The investigation conducted by WorkSafe uncovered a series of failings, including:

• There was no structured hazard and operability study prior to commissioning the

operation.

• PCR did not obtain a peer review of the proposed chemical process, plant, and

equipment from a competent person.

• PCR failed to ensure that there were safe ventilation arrangements for the chemical

processing container.

• PCR failed to ensure that a commercial proprietary pressure relief valve was used on

the processing container’s reactor.

• PCR failed to develop, document, implement, and communicate a safe system of

work for the operation of the process including detailed operating procedures.

• PCR failed to test its chemical process and processing container by ensuring that a

trial run was completed with a more benign raw material.

• PCR failed to take any steps to obtain a Hazardous Substances Location Compliance

Certificate and did not meet fundamental safety requirements to obtain a compliance certificate.

• PCR failed to notify WorkSafe, failing to display any signage on the outside of the Bromley building and inadequate signage on the process container itself, failing to prepare an emergency response plan.

• A safety data sheet was not prepared or readily accessible at the site for emergency service workers.

“PCR is experienced in handling and manufacturing hazardous substances but in this case, it would seem that their enthusiasm to create their own active ingredient has over-ridden the legal obligation to ensure their workers were protected.” Gardner said.

“It was an operation they knew was dangerous and could have potentially fatal consequences.”

*Original article online at https://www.nzherald.co.nz/nz/extremely-lucky-to-survive-company-fined-275k-for-poisoning-employee/NZXQV3QDQOOGS2UMTNHNV3YPPY/