Abstract

Technological and economic development have influenced the amount of post-production waste. Post-industrial waste, generated in the most considerable amount, includes, among others, waste related to the mining, metallurgical, and energy industries. Various non-hazardous or hazardous wastes can be used to produce new construction materials after the “solidification/stabilization” processes. They can be used as admixtures or raw materials. However, the production of construction materials from various non-hazardous or hazardous waste materials is still very limited. In our opinion, special attention should be paid to waste containing fluoride, and the reuse of solid waste containing fluoride is a high priority today. Fluoride is one of the few trace elements that has received much attention due to its harmful effects on the environment and human and animal health. In addition to natural sources, industry, which discharges wastewater containing F– ions into surface waters, also increases fluoride concentration in waters and pollutes the environment. Therefore, developing effective and robust technologies to remove fluoride excess from the aquatic environment is becoming extremely important. This review aims to cover a wide variety of procedures that have been used to remove fluoride from drinking water and industrial wastewater. In addition, the ability to absorb fluoride, among others, by industrial by-products, agricultural waste, and biomass materials were reviewed.

Keywords: solidification/stabilisation; fluoride removal; defluorination techniques; adsorption; industrial waste

Excerpts:

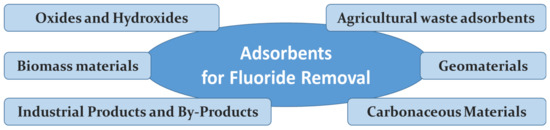

Large-scale industrial operations generate vast amounts of waste, the management of which can be a serious problem. An interesting possibility is to convert such waste into sorbents used for the water defluorination. Then, industrial waste becomes an adsorbent to remove fluoride from aqueous solutions [29]. Figure 1 shows selected types of industrial waste that are used as such adsorbents.

2. Anthropogenic Sources of Contamination with Fluorine Compounds

In many countries around the world, high levels of fluoride are the result of discharges of sewage polluted with fluoride [52].

Such wastewater is usually produced by industry: superphosphate fertilizers [63,64,65]; glass and ceramics production processes [66,67]; aluminium and zinc smelters [68,69,70]; steel production; uranium enrichment plants; coal-fired power plants; beryllium extraction plants; oil refineries [61,69,70,71,72]; the photovoltaic solar cell industry [61,73,74,75,76,77,78]; the production of high-tech silicon-based semiconductors [61,75,76,77,78]; and municipal waste incineration plants through HF emissions caused by the incineration of fluorinated plastics, fluorinated textiles, or CaF2 in sludge [79]. Fluorine is also used in electroplating. In addition, it is used as a melting point depressant in metallurgical furnaces in the smelting process. Water from mines can be a significant source of fluoride.

Chlorofluorocarbons (CFS) have been used extensively as gas in deodorants and coolants in refrigerators. However, due to their destructive effect on the ozone layer, some of these compounds are withdrawn from use. Fluoride also migrates to the environment due to the use of pesticides (e.g., cyhalothrin, fenfluthrin, and tefluthrin) [21]. It is also liberated into the environment in the brick production process [76].

It is estimated that about 30% of pharmaceuticals (including antibiotics, antidepressants, drugs against asthma, and atresia) are based on fluoride. The next big emitters of fluoride are cooling gases used in air conditioning, ventilation, and cooling devices contain fluorine in their composition [80,81]. Fluor is released into the atmosphere by burning hard coal, brown coal, and fuel oil. Then, industrial dust containing soluble fluorides and gaseous compounds (including HF) is emitted [82]. Wastewater from these industries has a higher F– concentration than natural waters, starting from ten thousand mg/L, and in the case of phosphate production, fluoride concentrations in wastewater can reach up to 3000 mg/L [83].

The combustion of biomass releases fluoride into the atmosphere, which is the main stream of this atmospheric pollutant, which has not been characterized before. The emission of fine particles (PM 2.5) of water-soluble fluorine (F–) from the biomass combustion was assessed at the Fourth Fire Laboratory in Missoula Experiment (FLAME-IV) using X-ray energy dispersive scanning electron microscopy (SEM-EDX) and ion chromatography with conductivity detection. Based on recent assessments of global biomass combustion, they estimated that biomass combustion releases 76 Gg F– per year into the atmosphere, with an upper and lower limit of 40–150 Gg F– per year. The estimated F– flux from biomass combustion is comparable to fluoride emission from coal combustion and other anthropogenic sources. These data show that biomass combustion is the primary source of fluoride released into the atmosphere in the form of fine particles that can be transported over long distances [37].

As the aforementioned fluoride-originated pollutants raise several health problems, the World Health Organization (WHO) determined the acceptable level of fluoride content in drinking water at the level of 1.5 mg/L [45]. However, the concentration of fluorides in industrial wastewater mostly exceeds these WHO guidelines, reaching even thousands of milligrams per litre [40,84,85]. Thus, fluoride pollution in the aquatic environment, caused by natural and artificial activities, has been a significant problem worldwide. Searching for new, effective ways to remove of fluoride-originated waste from water seems to be very important [60].